Want to learn how to make soap at home? It’s not nearly as difficult as you might be imagining! While most homemade soap recipes do require using lye, if you can measure and pour cake ingredients, you can make this homemade soap recipe, too!

Originally contributed by Jan Berry in 2017; this post has been updated.

My friend Jan, The Nerdy Farm Wife, has a book called Simple & Natural Soapmaking that’s filled to the brim with homemade soap recipes. She’s here to teach us all how to embrace the idea of making soap at home!

Making soap at home is a fun and satisfying DIY project. And better yet, making soap at home is not difficult. If you can follow directions and measure ingredients, you can make soap. It’s like making cake, except with safety gear. If homemade soap is something you’re interested in adding to your skill set, Jan’s book needs to be on your bookshelf.

Jan offered to share a basic homemade soap recipe with my readers and since making soap is something I know a lot of you would like to delve into, I jumped at the chance to have her share her expertise here.

Homemade Soap Recipe

This basic soap recipe will create around eight bars of unscented natural soap with a creamy lather that gently cleanses all skin types. If you’d like to further enrich your homemade soap with honey, oats or milk powder, follow the instructions below.

Take a Peek Inside My Book!

Get a free excerpt from my book, Attainable Sustainable: The Lost Art of Self-Reliant Living! You’ll also get my free weekly newsletter, complete with recipes, gardening tips, and a little peek at what’s going on around here — both the zany and the mundane.

When making soap, oils, fats and liquids should all be measured by weight and not volume. You need an accurate scale for making soap.

Never change a soap recipe without running it through a lye calculator first.

Not surprisingly, the idea of using a caustic ingredient like sodium hydroxide – commonly known as lye – has prevented even the most intrepid do-it-yourself-ers from learning how to make soap. Turns out, it’s one of those projects that is amazingly easy once you’ve gotten over your initial trepidation.

Saponification is the process by which soap becomes a cleaning tool. It’s a chemical reaction that occurs when oils and fats are exposed to a strong alkali like lye.

Every oil needs a different amount of lye to be transformed into soap. If you must make changes to a recipe, or want to develop one of your own, it’s essential to use a lye calculator to make sure that the ratios will produce a successful batch of soap.

Ingredients

Lye — is a corrosive ingredient, and must be used with respect (much in the way you use caution with bleach). It’s also crucial to the soap making process. While you’re using it, it’s important to take precautions by wearing a long sleeved shirt, safety goggles, and gloves.

Oils and Fats — The oils and fats that can be used in soap making are many, and the cost of the different options varies widely. This basic bar calls for a combination of coconut oil, olive oil, and tallow or lard.

While this is a basic soap recipe for home soap makers, you can change it up by adding one or more of the following add-ins, keeping in mind that the natural sugars in honey and milk powder can cause the soap’s final color to darken somewhat.

- ½ tbsp powdered milk (cow, goat, coconut), stir into the oils before adding the cooled lye solution

- 1 tbsp finely ground oats, stirred into the soap before pouring into the mold

- 1 tsp honey diluted with 1 tsp water, stirred into the soap before pouring into the mold

Soap Making Safety

- When lye is added to water, an exothermic reaction occurs. It’s not visible — there’s not foaming or color changing — but the water becomes very hot.

- Always add the sodium hydroxide — or lye — to the liquid. Adding the liquid to the lye can cause a reaction resulting in an eruption of materials.

- When working with the lye, always wear protective gear and work in a well-ventilated area — outside, if possible. If you must work inside, be sure to open a window and avoid breathing in the fumes.

- If your skin comes into contact with lye, run it under cold water for 15 minutes. If you get lye in your eyes or on a large area of skin, seek medical attention immediately.

- Never leave heating fats unattended, as they are flammable. The purpose of heating oils in soap making is strictly to liquefy solid oils and butters. Once that occurs, remove from heat.

Making Soap

Making Soap

Step one: Make the lye solution. Measure the lye and pour into the distilled water.

Step two: Prepare the oils. Because the coconut oil and tallow are solid at room temperature, you’ll need to melt these. Once melted, you’ll add the olive oil.

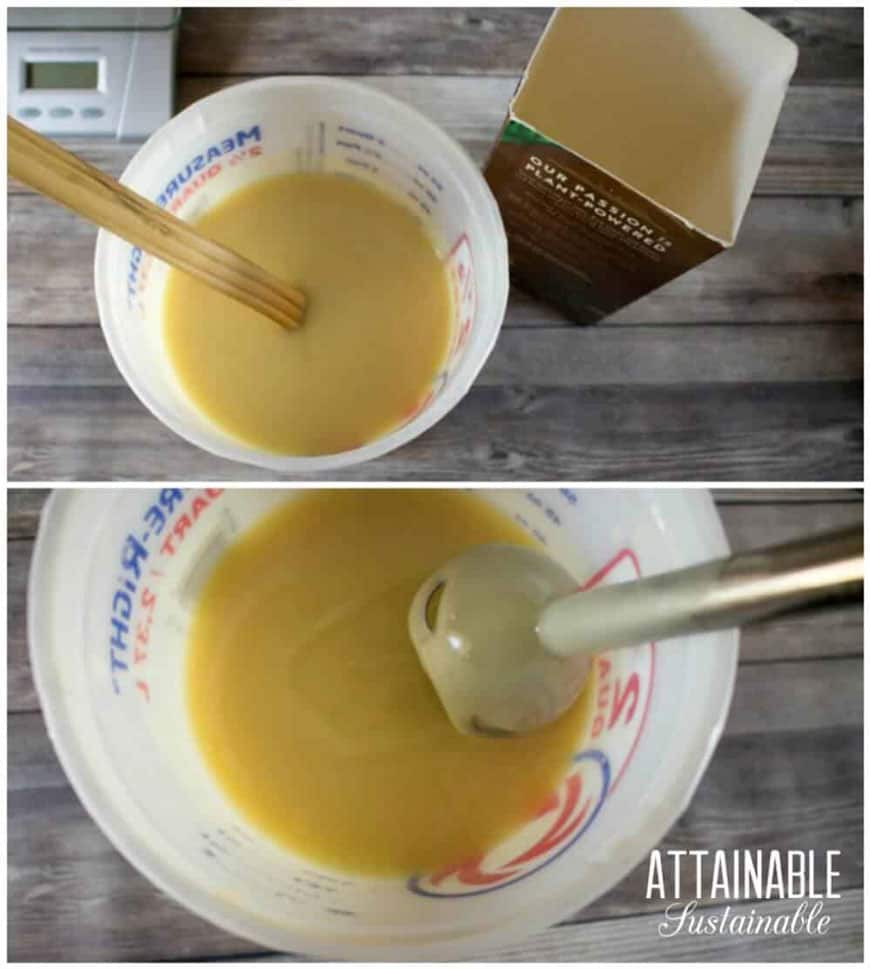

Step three: Pour the cooled lye solution into the warm oils and mix until the soap reaches “trace.” Add any extra ingredients you might like to use, such as honey, oats, or dry milk. An immersion blender can help to speed up this process.

What is trace?

Soap makers use the term ‘trace’ to describe the consistency of the soap batter when it’s ready to poured into molds. When the soap begins to look like a cooked custard and holds its shape across the top, you’ve achieved trace. Note that there isn’t an exactness to this, and the level of trace can range from light (thinner) to heavy (thicker). Mixing the batter until it reaches heavy trace allows for layering soap of different colors, as it holds its shape to support additional layers.

Step four: Pour soap batter into a mold. The batch shown uses a repurposed empty milk carton as a soap mold, but a Crafter’s Choice regular silicone loaf mold will also fit the size of this recipe perfectly.

Step five: After one to two days in the mold, release the soap and slice into bars. Cure the soap bars on racks or sheets of waxed paper for about four weeks before using.

This homemade dish soap bar is another soap recipe to add to your repertoire!

Basic Soap Bar

Ingredients

Lye Solution

- 9 oz distilled water 255 g

- 3.95 oz sodium hydroxide (lye) 112 g

Oils/Fats

- 14.5 oz olive oil 411 g

- 7.5 oz coconut oil 213 g

- 6 oz tallow or lard (*or substitute) 170 g

Instructions

Step 1: Make the Lye Solution

- Wearing protective gloves and eyewear, carefully stir the lye (sodium hydroxide) into the distilled water until dissolved.3.95 oz sodium hydroxide (lye), 9 oz distilled water

- Work in an area with good ventilation and be careful not to breathe in the fumes.

- The lye solution will get very hot, so set it aside to cool for about 30 or 40 minutes or until the temperature drops to around 100 to 110°F (38 to 43°C).

Step 2: Prepare the Oils

- Gently heat the coconut oil and tallow (or lard) on low heat until melted. When the solid oils are melted, take the pan off the heat and pour into the olive oil. This helps cool down the melted oil/fat, while warming up the room temperature oil. If you want to add powdered milk to your soap, blend it into the oils at this point.14.5 oz olive oil, 7.5 oz coconut oil, 6 oz tallow or lard (*or substitute)

Step 3: Mix

- Pour the cooled lye solution into the warm oils. Using a combination of hand stirring and an immersion blender, also called a stick blender, stir the soap batter until it thickens and reaches trace.

- Trace is when the soap has thickened enough so when you drizzle a small amount of the batter across the surface, it will leave a fleeting, but visible imprint or “trace” before sinking back in. Trace can take anywhere from 2 to 8 minutes, depending on how warm your ingredients are and how much you stir.

- If you plan to add honey and oats (see notes), blend them in well at this stage.

Step 4: Pour in Mold

- Pour the soap batter into your soap mold. Cover lightly with wax or freezer paper, then a towel or light blanket for insulation.

- Peek at the soap every so often; if it starts developing a crack, uncover and move to a cooler location.

Step 5: Cut and Cure

- Keep the soap in the mold for one to two days, or until it’s easy to remove, then slice it into bars when it’s firm enough not to stick to your cutting tool. Cure on coated cooling racks or sheets of wax paper for about four weeks before using.

- The soap is safe to touch without gloves 48 hours after making, but it needs the extra time to allow excess moisture to evaporate out so the bars are harder and longer lasting.

Notes

- To replace tallow or lard, try using 4 oz of cocoa (or kokum) butter plus 2 oz of sunflower (or sweet almond) oil. The lye amount will stay within an acceptable amount and won’t need to be changed.

- One or more of the following add-ins can be included in the soap recipe, keeping in mind that the natural sugars in honey and milk powder can cause the soap’s final color to darken somewhat.

- ½ tbsp powdered milk (cow, goat, coconut), stir into the oils before adding the cooled lye solution

- 1 tbsp finely ground oats, stirred into the soap before pouring into the mold

- 1 tsp honey diluted with 1 tsp water, stirred into the soap before pouring into the mold

- The batch shown uses a repurposed empty milk carton as a soap mold, but a Crafter’s Choice regular silicone loaf mold will also fit the size of this recipe perfectly.

- Be sure to try your new soapmaking skills to make this homemade dish soap, too!

Making Soap

Making Soap

How long does it take to cure?

Cure on coated cooling racks or sheets of wax paper for about four weeks before using.

Can you make the process any faster? Like 2 or 3 weeks?Luk

If you use the hot process method this hastens the time you can use it, since it bakes out yhe lye and neutralizes it. I prefer this over the cold process for this reason. I check the ph after cooking it in the pressure cooker before setting it up in molds. It should be between 8-10. After 24 hrs I cut it then set it on wire racks where I have a fan running overnight for a few days up to a week to harden a little more especially if I’m gifting them. However for my family, we will use it within a day or two provided the ph is around 9. Best to you!

I was wanting to do a swirl design. Does this recipe work well for swirl designs or color layering? Thank you btw.. i love that you added a vegan alternative direction. Its sometimes tricky for me to figure that out on my own.

I have not tried swirling !

If you use the hot process method this hastens the time you can use it, since it bakes out the lye and neutralizes it. I prefer it over the cold process for this reason. I check the ph after cooking it in the pressure cooker before setting it up in molds. The ph level should be between 8-10. After 24 hrs I cut it then set it on wire racks where I have a fan running overnight for a few days up to a week to harden a little more especially if I’m gifting them. However, for my family, we will use it within a day or two provided the ph is around 9. Best to you!

Curious though..wouldn’t the lye contaminate the water in rivers and lakes, oceans, etc? Is lye a natural product?

With the exception of glycerin soap, all bar soap is made with lye. Without it, there’d be no soap. The lye is “used up” in the saponification process of soap making, turning the oil into soap. As long as it’s made properly, there shouldn’t be any lye remaining.

really it is informative

Hi, I am new to soapmaking and want to ask: I put the grams of the oils in soapcalc.net, but i received different amount of water – 300 ml, instead of 255… I’ve tried to make “10 % super fat”, the amount of water remained 300, just the lye amount decreased to 105… or something. Here i want to ask is there eny different soap calculator, and also is the amount of the water different if we will make HP or CP? Also – if it is different – how i have to calculate how much water to lye it must be, on order to make good HP or CP soaps? Thank you!

Hi Krista! I usually use the lye calculator at Majestic Mountain Sage (https://www.thesage.com/calcs/LyeCalc.html). It gives a suggested range of water – picking an amount near the middle of the range is usually a good guideline for cold process. (Example: If it suggests 7 to 10 oz, try 8.5 oz water.) Virtually all of my recipes are superfatted at 5% or 6%, I wouldn’t really go much higher or you could end up with a too soft/oily soap that takes a long time to cure. (Exceptions are pure coconut oil soap or salt bars – they can go as high as 20%!)

Soapcalc has a default number set at 38% water (it’s the #3 spot on their calculator, it says “Water as % of Oils”). This number is fairly high for cold process soaps. However, when you’re making hot process soaps, it’s a great number to go with, as the higher amount of water will help keep the soap from drying out as it cooks.

Many soapmakers find that reducing the water amount (also called water discounting) helps palm-free soaps like this one reach trace faster and set up in the mold quicker. You can definitely use the default amount of 38% on SoapCalc, but if you do, I recommend adding sodium lactate or 1 tsp of salt to the lye solution so the soap is able to harden up in the mold sooner. Alternatively, you can change the number on the calculator so it’s lower – instead of 38%, try 33% (or a little lower) and I think you may find your soap enjoyable to work with.

The more batches of soap you make, the more you’ll get a feel for how much water you like to use. Oils and lye should be precise, but water amount is VERY flexible! Some soapers like less water, while others like a full amount. The wonderful thing about soapmaking is that there’s room for all sorts of variations like that, and you can still make a wonderful soap! 🙂

Thank you, Jan! I didn’t know that! Now i understand why my palm free soaps are going so fast 🙂

Somehow I totally missed this response. Thanks for chiming in, Jan!

I have been making melt and pout soap and wanted to make a lard soap. I asked many and was told to not make a 5 lb. loaf. I’m stubborn and made a 5 lb. wooden mold. You showed me the numbers I need for your soap and I did a calculation for straight lard soap as well and have both sets of numbers. ( I will make (2) 5 lb. batches. Thank you so much you taught me a lot in a short amount of time.

Glad this was useful!

For safety reasons, all soap recipes should be verified with a soap calculator to make sure that the recipe is at the very least lye neutral; super fatting is preferable. There are a number of soap calculators online.